Lead Crtstal Battery Presentation

THE BATTERY FOR NOW AND THE FUTURE

LEAD-ACID BATTERIES

THE PROBLEM

Traditional lead acid batterieshave many defects. This is due to the inherent structural characteristics,

which include:

• Plate sulfation

• Active material loss

• Dehydration

• Serious acid pollution

• Short cycle life

• Poor low/high temperature characteristics

THE SOLUTION

To overcome the structural defects in lead-acid batteries, manufacturers started using AGM and a

gel electrolyte in batteries. Although this did not solve all the problems, progress was made by:

• Reducing the acid mist

• Reducing the water loss rate

• Reducing the self-discharge rate

• Improving the discharge capacity

By solving these problems, a new series of challenges were introduced:

• Poor electrode penetration by the gel electrolyte

• Weak capacity of AGM separator match

• Slow electrode reaction

LEAD CRYSTAL BATTERIES

THE DIFFERENCE

In order to overcome the fundamental shortcomings of the lead-acid and AGM or gel batteries, the

LEAD CRYSTAL BATTERY uses new proprietary technologies, including:

• Silica crystalline state SiO2 composite electrolyte (NOT A GEL) to replace the conventional

sulfuric acid solution

• The preparation method of the Silica crystalline state SiO2 composite electrolyte

• The irrigation fluid device, and its battery plus liquid method

• Battery terminals connected to protective devices

• Batteries with liquid shunt valve

• New plates

• New AGM

LEAD CRYSTAL BATTERIES

DIFFERENCE RESULTS

As a result, this self-designed SiO2 cleaning composite electrolyte replaces the conventional sulfuric

acid solution/gel. A number of unique and advanced technologies are used in the manufacturing of

the Lead Crystal Battery in order to solve the lead-acid/gel battery problems. This includes:

• Virtually no plate sulfation

• No active material loss

• No dehydration

• No acid pollution

• Excellent cycle life

• Very good low/high temperature characteristics

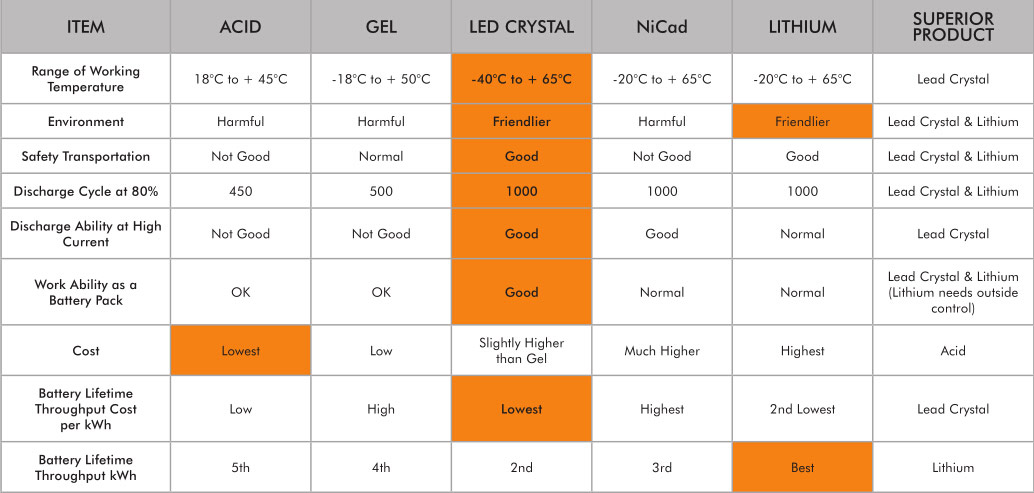

LEAD CRYSTAL BATTERY - COMPARISON TABLE