BPC series Batterie lead acid accumulator control points

BPC series Batterie lead acid accumulator control points

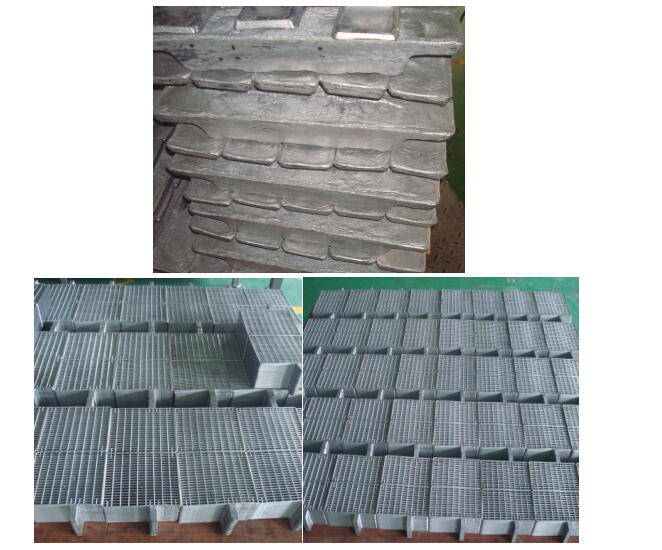

1, independent technology to produce lead-calcium-tin-lead alloy and multivariate optimization computer-aided design grid, with excellent electrical conductivity, corrosion resistance and passivation capability.

2, independent formula and process for producing high-density active lead paste, double coated with a special control Board technology, a stronger cycle endurance capacity.

(Note: double-sided coated board needs to ensure that both sides of the plate is not exposed grid ribs).

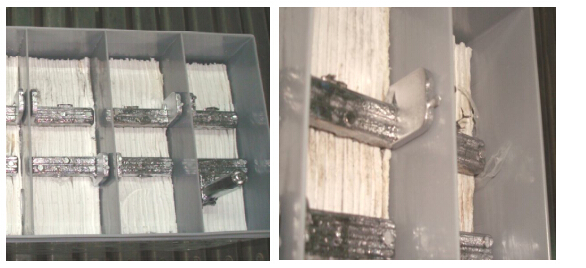

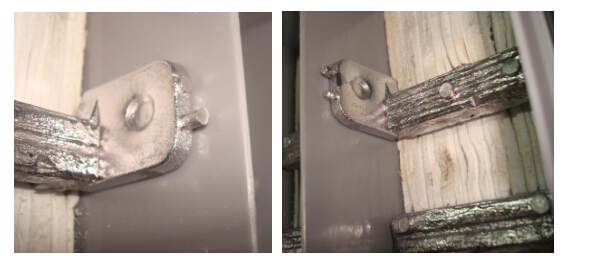

3, advanced welding and wear a cast pole group wall welding technology, ensure welding firm and low resistance.

1 complete automatic casting welding electrode group, wait wear wall welding

2 complete automatic welding through wall

3 through the wall weld quality inspection (automatic detection of resistance)

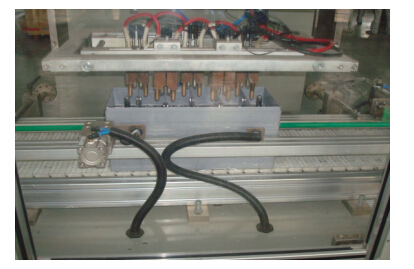

4. Special acid injection technology and precision cold acid technology to improve battery uniform consistency.

5. The full range of battery in the formation process using its own technology without pumping acid, efficient and environmentally friendly.

(Note: The pumping acid process, need to be installed at the top of the pot rich liquid battery using precision injection hole Jinyue Cheng.

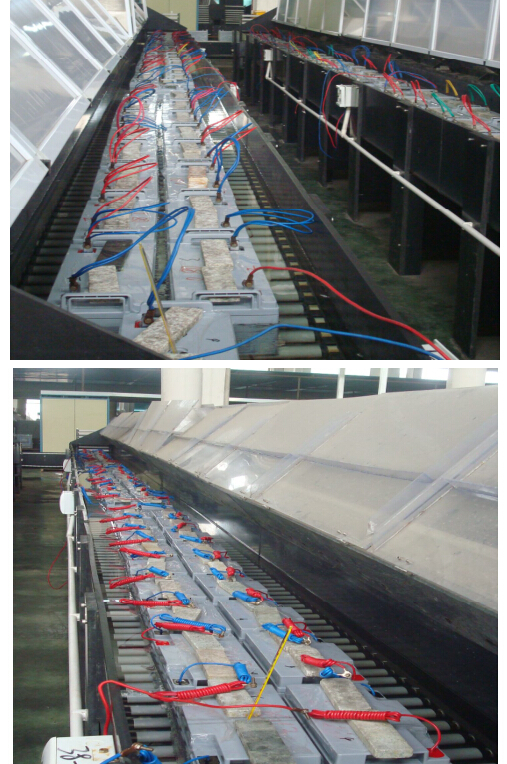

Quantitative acid filling, no need to install flooded maker. Specifically as shown in the following picture. )

6. The self-developed AGM-GEL technology, with superior deep cycle performance.

More BPC series battery:

long life ups battery 12V 100AH