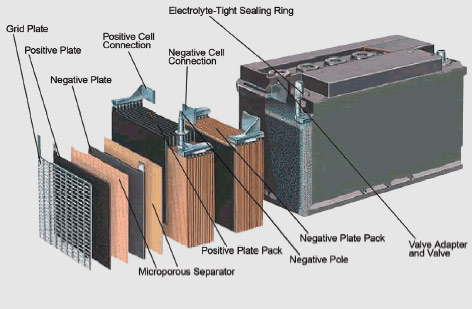

Main Components of AGM GEL Battery

Main Components of AGM GEL Battery

| Item | Component | Main Characteristics and advantages |

| 1 | AGM Separator | Now we use glass fibre Absorbed Glass Mat and absorbed plenty Gel and acid electrolye with good tensile property.Compared to PE or PVC separator, AGM separator with better resilience and small internal resistance. Through the chemical lab testing, after long time boiled in H2So4 electrolyte with high temperatures, the AGM separator still in good condition. |

| 2 | Epoxy | We use professional Epoxy with good seal performance which can last at 15 years. All the batteries has tested the seal performance before shipment through the barometer. |

| 3 | ABS Plastic containers | The ABS has better mechanical property than traditonal PP case.It has low temperature impact resistance and not easy to deformation.The contractibility rate of ABS is at 0.4-0.9% but PP at 1.6%-2%. This can ensure the ABS container not easy loss water and avoid dry the battery. |

| 4 | Gel Electrolyte | Our SiO2 GEL is original made in Germany. Use vacuum Gel filling machine , the Gel electrolyte permeate in to AGM separator homogeneous. Compare to using the PP or PVC separtor, the Gel can be even distribute in the separtor instead of staying in the bottom area. It can improve battery chemical action and increase battery discharge efficiency. |

Date: Dec 12, 2016

Issued by: Mr Xu Mingsheng (CTO)