The principle of valve - controlled lead acid battery and the action of electrolyte

As a key component of the UPS, the valve-regulated lead-acid battery can provide the reserve energy for the load equipment at any time in the event of power failure or abnormal power grid. The importance is self-evident. Since the battery is usually in a charging or standby state, an abnormality may not be discovered in time, and it is discovered when necessary that the loss has been caused and cannot be recovered.

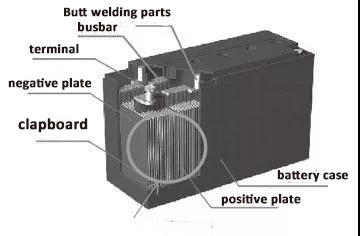

1. Valve-regulated lead-acid battery

2, valve-controlled lead-acid battery charging and discharging principle

The battery uses the electrochemical principle of cathode absorption, and its chemical reaction is as follows:

During discharge, the lead dioxide in the positive electrode plate and the spongy lead in the negative electrode plate react with sulfuric acid in the electrolyte to form lead sulfate and water. As the reaction progresses, the concentration of sulfuric acid gradually decreases, and the terminal voltage gradually decreases; When charging, lead sulfate is converted into lead dioxide and sponge lead, respectively, and the concentration of sulfuric acid is gradually increased, and the terminal voltage is also increased.

3. The role of acid in valve-regulated lead-acid batteries

In the chemical reaction of the battery, the electrolyte acts as an ion between the ions and participates in the chemical reaction of the battery.

The electrolyte is prepared from pure sulfuric acid (H2SO4) and distilled water in a certain ratio, and its density is generally 1.23 to 1.32 g/cm3 (20 °C).

Battery open circuit voltage = battery acid density +0.85 (single cell 2V module). If the battery acid density is less than 1.2 when the liquid leaks, the normal chemical reaction cannot be performed inside the battery, and the battery is abnormal and cannot be used normally.

4. Analysis of the causes of rupture of valve-controlled lead battery housing

The battery case usually uses ABS resin, but if the manufacturer's material selection is unreasonable, such as the selected battery case is a plastic that is easy to break, even for cost, the secondary material is added during the molding process, so that the strength and toughness of the outer casing are insufficient, with the internal The pressure changes and cracks are generated.

For more about manufacturing Lead Acid Battery products, please visit https://www.bullsbattery.com/